Picking the Right (or Wrong) Pick and Place Machine

The need

Back in August 2018, we got ourselves a desktop pick and place machine from China (there’s a reason why we didn’t talk about this earlier, read on). We wanted to speed up our in-house production that was only equipped with a mighty tweezers. Limited by a small budget and space constraint (plus a door width of 80 cm), we went on to look for one. We knew exactly what we want and here are some of the requirements:

- Vision system for parts alignment – without vision system to correct misaligned components, there will be too many manual touch up work by hand

- Supports different nozzle sizes for various component size to be able to complete a job without stopping to change the nozzle manually – most lower cost machine comes with either single or dual head that holds 1 or 2 nozzle at a time, therefore a nozzle changer is needed

- Enough feeders to support most of our BOM lists – the boards we made have BOM lines as low as 10 going all the way up to 40 different types of components where mostly comes in 8 mm tape width reels and remaining in 12 mm and 16 mm tape width reels.

- Support loose components in tray – as we don’t build boards in the thousands at a time, costly parts like microcontroller and power management controller comes in either the format of tray or a reel of 1K to 5K. We couldn’t afford a full reel and hence tray was the only option for us or pay some fee for re-reeling services like those offered by Digikey or Mouser.

- Support components in tube packaging through vibration feeder – some components comes in tubes and components in this packaging can be loaded using a vibration feeder

- Budget – we can only afford to fork a maximum of USD5K so we limit our purchase within that amount

- Size – not too big, too heavy and it must be able to go through our 80 cm width door

Smallsmt VP-2500D desktop pick and place machine

It is a dual-head with vision system desktop pick and place machine with push feeders from SmallSMT. So we shipped a chunk of money over the South China Sea and waited for about 3 weeks for the machine to arrive. We arranged our own shipment from China to Malaysia by sea as it was a lot cheaper and it takes only a week to arrive. Surprisingly here in Malaysia, pick and place machine is exempted from taxes. We were hoping that it could speed up our assembly process so we could concentrate more on the development work of our products. We were so excited when we first received the machine and to play around with it. After tinkering around with the machine for few weeks, we are pretty much familiar with the software and process involved. But, this is when we started to run into many issues on the machine. Here are some of the issues we came across:

- Main board went kaput – The very moment we installed the vibration feeder that comes with the machine, it started to make a loud noise and that is when we knew something was not right. It turns out that the driver of the vibration feeder located on the main board is damaged and is driving the motor on the vibration feeder well beyond it’s maximum rating. SmallSMT told us it was due to the short circuit caused by the vibration feeder metallic body. We find this rather absurd because there was isolation between the vibration feeder electronics and the chassis of the pick and place machine. Anyhow, they sent us a replacement main board albeit it sure looks like a board that has been used before and repaired judging from the amount of flux residue from hand soldering on the new main board.

- North feeder working inconsistently – A bulk of our time spent on the machine was on configuring the push feeder. It is at best described as “fiddly” and “inconsistent”. It would work perfectly during the setup process, but would then fail to accurately advance the tape of reels during normal operation. This resulted in countless halted job anytime in a pick and place job. But, what baffled us was why it would run almost perfectly on the west feeder but not on the north feeder? We tried every tricks and method suggested by SmallSMT but most of the time it would work fine for a short while before going back to it’s old self. We desperately need the north feeder because there is where our components that comes in 12 mm, 16 mm and 24 mm tape width reels can be installed. Even more shocking, SmallSMT told us the 24 mm feeder is actually not supported! Why sold it to us at the first place?

- Reel cover tape snapping way too often – The machine uses a push feeder (instead of a drag feeder) to advance the component reels. A mechanical cover tape peeling mechanism will pull the cover tape towards the back to expose the component to the pick and place head. How tight or lose the tension on the cover tape can be adjusted to one of the 3 settings on the machine. However, even at the least tight setting, the cover tape on our component reels snap way too often. Again, this resulted in countless stop on the pick and place job.

- Some feeder pick up locations are not reachable by the top camera – In order to configure the pick up location, we need to move the head manually to the pick up location without vision assistant. This process needs trial & error and we spent a lot of time here. The vibration feeder is one of the location not accessible by the camera on top of few other push feeders.

- North feeder location not accessible by the head – this is one of the most shocking issue we faced on the machine. When we try to move the head to any of the 8 mm tape width feeder on the north side, the software will complain it is not reachable. A solution given by SmallSMT was to shave off a portion of the y-axis limit end stop. We reluctantly shaved off 2 mm from the y-axis limit end stop metal piece. Even though this solved the problem, we start asking our self, isn’t the machine calibrated and tested at the factory to detect such issues? Or it was not even calibrated? After the fix, the top camera will no longer park at the machine origin (indicated by a engraved mark on the machine bed) when the homing function is executed. An offset of 2 mm was also needed on the software to tell the machine everything has been moved by 2 mm on the y-axis.

After spending few months on the issues of the machine, we went back to the tweezers. We have since put the machine on sale on the EEVBlog forum and if anyone feels that they could make full use of the machine better than us, drop us a mail. We have sold the machine to a gentleman in Romania.

Re-tuning our requirements

When we decided it was time for us to look for a second pick and place machine, we narrowed down our list to a few machine sub USD10K prices (we decided not to be fully limited by our budget). We have since tweaked our initial requirements for our machine:

- Removable feeders – it is our mistakes on our first purchase to

thinkassume that fixed feeders are easily manageable and reels can be swapped in and out without much trouble. Oh boy, we were so wrong. - Industry proven removable feeders – removable feeders are expensive, full stop. The total cost of the feeders alone could easily equal that of the machine cost. By having machine with industry proven feeder, we will not be

locked downheld ransom to a propriety feeder made by the machine manufacturer. This bring us to the tested and proven pneumatic Yamaha CL feeder that were used on the Yamaha YV and YG series machine. There are still abundance of these machine available in the 2nd hand market and they are built like a tank. A lot of newer machine from China uses these Yamaha CL feeder due to it’s reliability, robustness and cost. If you dig deep and spend some time looking, Yamaha Cl feeder can be had as low as USD40 for variant supporting 8 mm tape width. In the 2nd hand market, we found some retailing at USD15. Obviously, these feeder even brand new ones are no longer original feeder made by Yamaha but clones. However, due to it’s simplicity (at least in the feeder design world), they are copied to perfection. - As many head as possible – we figured out that having an automatic nozzle changer is a very cool feature but it also introduces another problem (at least on our previous machine). Whenever a nozzle is being changed, this introduce some amount of error and deviation due to the fitting of the nozzle to the head. 4 heads is minimum and 6 & 8 heads is widely available for larger machine. Based on our BOM of various designs, having 4 different nozzle is enough to complete a pick and place job without changing the nozzle.

- Conveyor belt – we think this is a very convenient mechanism to load the PCB onto the machine. Having to place the PCB to a fixture manually is really time consuming. Furthermore, if we decided to expand our manufacturing lines, we can cascade several machine in the same line or add automatic stencil printer with reflow oven that comes with conveyor belt too. This is not possible if the conveyor belt feature is not available.

- Widely used by factories and not some Youtuber – this is one of the mistake we made and this is one of the reason (if not the most important reason) on which machine we ended up with the 2nd time around. As we dig deep into the small scale PCBA manufacturing in China, we do notice many of these factories are either using 2nd hand machine like those older Yamaha (YV/YG), Juki, Samsung, etc machines or brand new made and designed in China machine. Due to the space issues, we obviously cannot fit a big machine like those 2nd hand machine. While those brand new made in China machine comes in variety sizes and specifications.

- As many feeder as possible – no feeder is too much.

Potential candidates

After some extensive research we narrowed down our candidate list to the machine listed below. They are all desktop/benchtop machine that could go through our 80 cm door.

| Specifications | Wenzou ZhengBang | Kayo | Boreytech | Huawei Guochang |

| Model | ZB3545TP | A4 | SMT-W1-F | HW-T4SG-50F |

| Mounting heads | 4 | 4 | 6 | 4 |

| Feeders | 38 | 46 | 52 | 50 |

| Motion drive system | Belt | Ball screw | Ball screw | Ball screw |

| Camera | 5 + 1 | 5 + 1 | 1* + 1 | 5 + 1 |

| PC | Built-in | External | External | Built-in |

| Smallest component size | 0402 | 0402 | 0402 | 0201** |

| Largest component size | 22 mm x 22 mm | 40 mm x 40 mm | 25 mm x 25 mm | 40 mm x 40 mm |

| Minimum component pitch | 0.5 mm | 0.3 mm *** | 0.5 mm | 0.3 mm *** |

| Maximum z-axis movement height | 12 mm | 20 mm | 15 mm | 20 mm |

| Weight | 120 kg | 240 kg | 200 kg | 210 kg |

| Price (FOB) | $6000 | $7500 | $7600 | $6580**** |

| Optional electrical port | – | – | – | $350 |

* flyby vision camera

** using optional electrical feeder

*** maybe over specked advertised

**** FOB destination (to Malaysia) supplied by Glichn (HWGC reseller for export market)

A trip or two to China

As we are based in Malaysia in the center of South East Asia, we are spoiled with cheap flights to China. This allows us to go on short trips lasting 2-4 days for few hundred dollar. We went to Shenzhen, China back in August 2019 and another trip to Beijing, China back in December 2019 (yes! when CoVid-19 was still not considered a worldwide threat).

Shenzhen August 2019

A super short trip of 2 days 1 night jammed packed with machines to evaluate. The trip basically consist of 2 parts spread across 2 days:

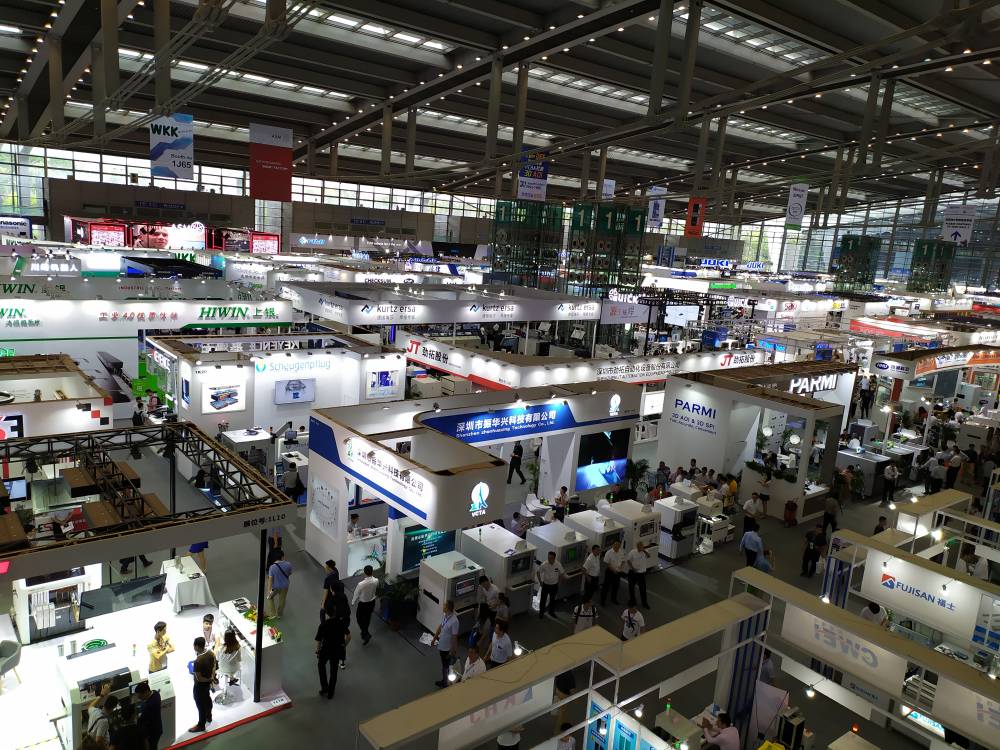

Shenzhen NEPCON 2019

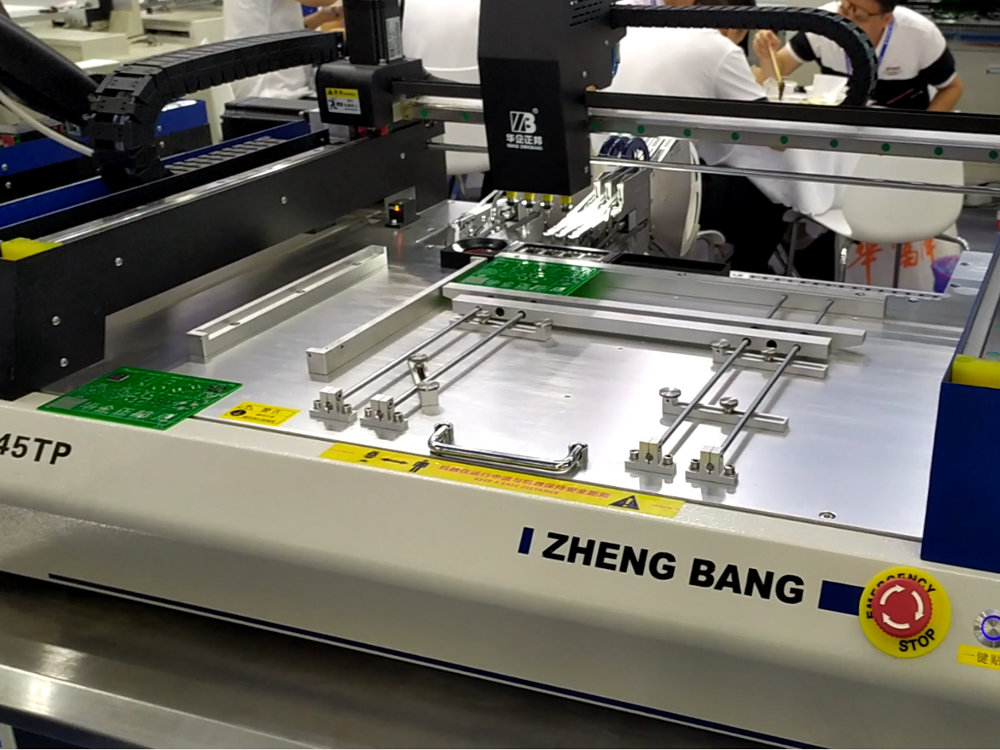

We always made it a habit to travel light even when travelling abroad. The first thing we did after taking the subway from the Shenzhen airport to the city was checking out the exhibition due to the time limitation. That lightweight backpack made it possible to move around such a big venue. This is where we get to check out several machines that we were interested in. We knew ZhengBang and Charmhigh were going to exhibit there on top of the regular big boys like Yamaha and Juki. It was nice to actually meet the people from Wenzhou ZhengBang and checking out the ZB3545TP. This is one of the earliest machine we look at due to it’s size and it’s easy to use software. It was not due for release at least until the exhibition at Shenzhen NEPCON 2019 in August 2019. The sales representative were not giving much information other than it support 38 feeders (8 more than the existing ZB3545TS), 4 mounting head, 4 small camera for small components and a larger higher definition camera for larger components. We were told it was going for a special pricing of USD4500 during the exhibition. Little that we know that this newer ZB3545TP is a belt-driven machine unlike the ZB3545TS that is ball screw driven until we actually saw it in person. This left a bad first impression on how after sales and support might shape up if we were to buy one. We actually spent a lot of time on learning their machine software posted on YouTube and it is probably the easiest of the lot to use. But again the deal breaker here was how we were not informed in advance about the belt-driven system on the ZB3545TP and also the removal of the simple and repeatable nozzle calibration process that were employed on the older ZB3545TS. At the end of the exhibition, we decided that the ZB3545TP was not for us.

There are other similar sized companies like Charmhigh at the exhibition offering similar sized machine but before the trip, we did ask them on whether they would release any new machine or any upgrade plans on their existing benchtop machine like the CHMT560P4 which has 60 feeders capacity. The answer is pretty straight forward in which they said they are concentrating on larger machine and benchtop machine are no longer a priority. That is when we decided to skip putting any effort on checking out their machine. But their new CHM-861 flagship monster machine sure looks promising.

The regular big player was present at the exhibition like Yamaha, Juki and Autotronik just to name a few. But, their offering is beyond our budget and dimension requirements. We left the exhibition before the sun sets in a disappointing manner. But, in a way we managed to cross out one of the machine candidate out of the list. We ended the day with a warm bowl of dumpling before hitting the sack after a long day (we traveled from midnight the day before!).

Dumpling

Set

Pickle

Wenzhou Yingxing Technology Huawei Guochang Shenzhen factory visit

Huawei Guochang (HWGC) is fairly unknown to anyone outside of China at least a few years back. Their machine are mostly sold outside of China by reseller such as Wenzhou Yingxing Technology and Beijing Glichn. This allow their machine to be easily purchased outside of China through e-commerce website such as Alibaba and Aliexpress. We first contacted Wenzhou Yingxing Technology to inquire about the HW-T4SG-50F (sold as SMT550 by them). When they know that I was going on a trip to Shenzhen, they mentioned they have a factory in Shenzhen that we can drop by to look at the SMT550 and other bigger machine like (SMT660 and SMT880 which are all rebadged machine made by Huawei Guochang). On the morning of the 2nd day of our trip, we got up early and hit the subway plus taking a DiDi for the first time in China (your Uber and Grab in China) to the factory. Upon reaching the area of the factory, we were searching for at least 15 minutes because there were no company sign board to be found. We were lucky as some friendly people working in one of the building that we entered wrongly managed to figure out which factory building we wanted to go. To our surprise when we reached the front door of the factory, we were greeted by a big HWGC signboard. That is when we get to know that we are actually visiting a HWGC mini showroom or sales office in Shenzhen!

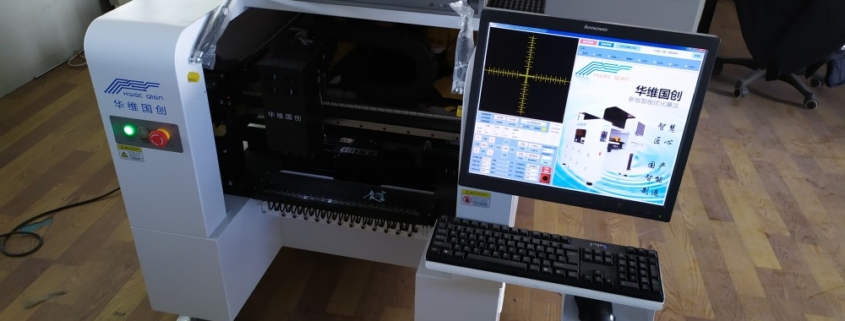

We were greeted by representative name Mr Guo that runs the place. Instead of using the sales office just for displaying their machine, they actually run a small production house there. They have a unit of their 6 head 64 feeders machine (HW-T6SG-64F) and an 8 head 80 feeders machine (HW-T8SG-80F) cascaded in line equipped with a semi-automatic stencil printer. They were assembling a batch of ESP8266 boards with components size down to 0.4 mm pitch and 0402 passives. As all their machine supports electrical feeders (ask for it when ordering if you need one), the larger 80 feeders machine on the left were loaded with electrical feeder to handle smaller components while the 64 feeders machine on the right were loaded with regular pneumatic feeder for larger components. We managed to observe how good the placement of components are with these machines and most components were spot on sitting on where they should and only occasionally a component or 2 in a panel sitting slightly off but the reflow process would nicely tuck them back into position for such small displacement. We are impressed because it was running at full speed (more than 10k CPH)!

Of course our trip was not about these bigger boys, unfortunately. The machine that were looking at were just released about a month or two but luckily a new unit just came in few days ago. Unfortunately, they have yet to setup the new machine. But, not all is bad news as we get to measure the dimension of the machine in real life to ensure it goes through our door (remember our 80 cm width door?). We actually like the simple design and how solid the build is.

As we were chatting with Mr Guo, we were surprised that they actually have customers in Malaysia using the machine for production. We left Shenzhen that night itself with more or less knowing which machine we will purchase. But, the dilemma was should we continue to purchase from a reseller that speaks English (somewhat) or deal directly with HWGC? Mr Guo did mentioned they are fine in both situations but we knew there would be a language barrier issue for technical support. As much as we can speak in Mandarin (mostly on how to order food LMAO), it’s a totally different ball game when it comes to technical terms. In less than 4 hours, we are back in Malaysia!

Beijing December 2019

Come December 2019, we had some conversations with Kayo and Boreytech regarding their machines. Both companies were providing us with many videos on machine software usage and real production samples. But, we found out that both machines require an external PC to operate. On top of that, support for using electrical feeder is not out of the box, they need to add them which we believe would not be a neat solution. At the same time, we started to use the Alibaba platform more often to see what other options are available in the China market. Little we know that sellers on Alibaba can actually check out on which customer has been browsing their products. This brought us to a HWGC reseller company called Beijing Glichn that were selling the HW-T4SG-50F as GP400 at a cheaper price than other resellers of the same machine. They offered to bring us on a HWGC factory tour in Beijing. Coincidentally, all three companies (HWGC, Kayo, Boreytech) are located in Beijing, China! That was when we decided that we needed to hop on the plane again.

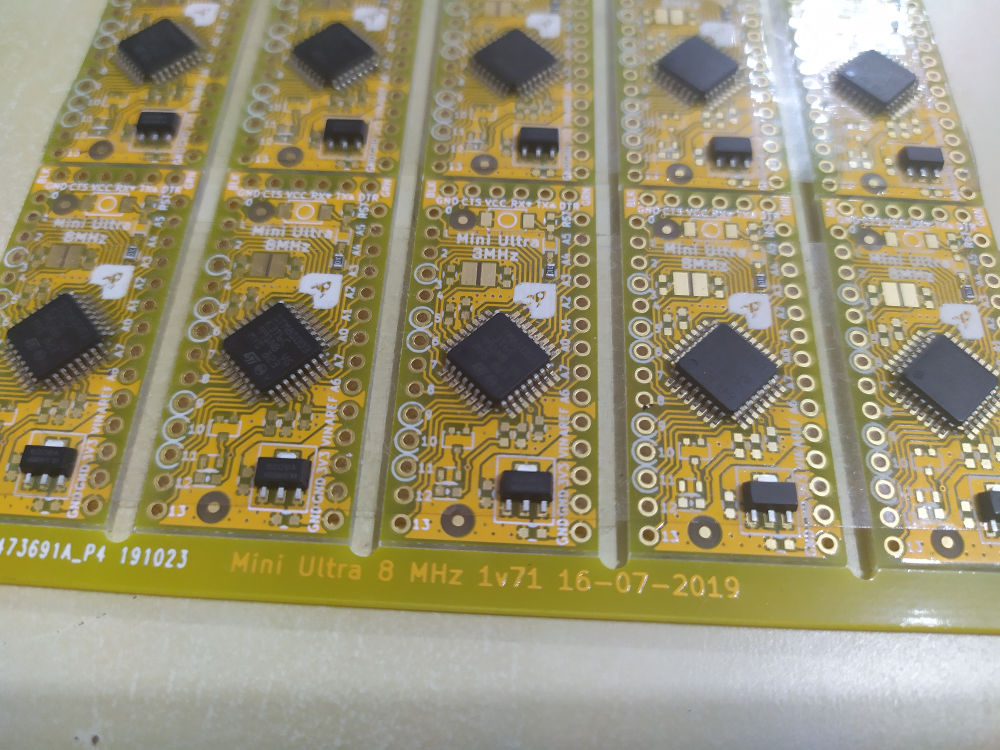

We told remind ourselves that we need to actually try out the machine candidates with our very own PCB this time around. This proved to be a tough ask but doable. We knew how strict China custom is in bringing in stuff into China. It would definitely look weird to bring some electronics components (in reels!) into China when bulk of them are produced there. We selected our simple Mini Ultra 8 MHz PCB to test them on the machine in China. Instead of bringing our components from Malaysia, we purchase them in advance from Taobao and sent them over to the HWGC factory. We basically bought:

- A used TQFP-32 JEDEC tray for RMB1! Shipping was RMB25 though using fast express

- 10 pieces of unknown STM MCU in TQFP-32 package similar to the ATMega328P used in our board. IC will be loaded onto the JEDEC tray.

- A reel of 10K 0603 resistor that will be loaded on an 8 mm feeder.

- A reel of XC6206P332PR regulator in SOT-89 package similar to the MCP1700T-3302 used in our board. Reel will be loaded on a 12 mm feeder.

We reached Beijing on a cold sub zero morning that was so uncomfortable for someone that lives under the hot sun 365 days in a year. Alas, after dropping off our already light backpacks at our Airbnb, we jumped onto the subway and traveled as far as the subway line could bring us to the north of Beijing. At the last station, a sales representative name Ms Karen Peng and her colleague from Beijing Glichn picked us up to the HWGC factory. We were greeted by the engineers at the HWGC factory that were suit up with their company yellow and black windbreaker (wondering why they didn’t paint their machine in that color which would be very cool) and a stash of yet to be assembled machine frame/body.

They have prepared a machine to test out our PCB. We also noticed that all our components purchased from Taobao has arrived safely on the premise prior to our visit. The engineer took about 15 minutes to set up our PCB and did a trial run of mounting process. We managed to observe on the flow of work to use the machine. Although we brought our PCB pick and place file with us, the engineer decided to do it manually by specifying the coordinate of the components on a single PCB and multiplying them across the entire panel. It’s amazing how fast he can do it without much fuss.

We did a few runs of the pick and place process (we should have brought more copies of PCB, we ended removing the components from the double sided tape after each run!) and here’s an example of the accuracy. We can say they are mostly spot on, but the direct use of the PCB pick and place file would probably produce an even more accurate result. Again, it’s pretty much mirrored what we have seen at their Shenzhen office on the larger machines.

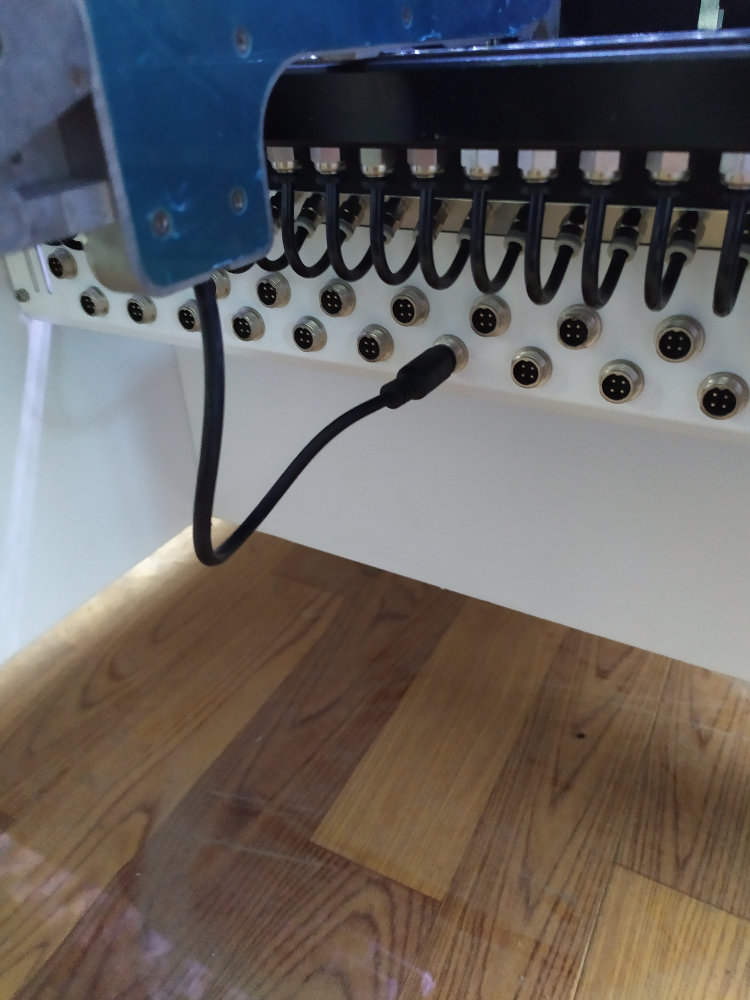

One important feature that we think could be useful for us in the future is the ability of the machine to use electrical feeder. They claimed their machine can pick and place components down to the size of 0201 using their electrical feeder. Here’s a sample of an 8 mm electrical feeder mounted on the machine.

8 mm electrical feeder

Cool LED indicator on electrical feeder

Port supplying power to electrical feeder

After spending about more than an hour, we decided to make a move as we can see everyone is so busy doing something. It’s best to let them to continue on their work. Before we leave, they showed us around their factory. Never in our life, we saw so many pick and place machines!

We left the HWGC factory in an even more freezing condition as night falls. Everything turns dark after 5 PM which was first for us. We wanted to thank Beijing Glichn for making the tour and test possible and they are kind enough to send us back to the same subway station they picked us up earlier in the day. Before we came to Beijing, we left the option of visiting both Kayo and Boreytech factories open although we didn’t make any arrangement with those companies. But after seeing what the HW-T4SG-50F is capable of, we decided not to waste their time on a visit that would not turn into sales. Our heart has already set on the HW-T4SG-50F, suffice to say.

We spent the next 2 days doing touristy stuff like visiting the Great Wall of China and Forbidden Palace. It was an icing on the cake for the trip.

The Forbidden Palace

The Great Wall of China

Tiananmen Square

The Chosen One

We can say that our trip was a success and we finally crossed out all the machines from the list except HW-T4SG-50F. We have decided to purchase them from Beijing Glichn as we knew language would become a barrier if any technical issues arise. The people behind both companies are also very warm and competent in what they do.

Epilogue

Unfortunately, then came the whole Covid-19 virus pandemic that affects the entire world. We were lucky we came back safely as early as in December 2019, it was reported that the virus was already in its initial stage of spread in China. China went into lock down mode as well as here in Malaysia shortly after that. Everything came to a halt and the future became unclear. Buying a machine would be a big risk and we were holding our wallet tight. Companies downsizing and closing down, people losing their jobs, industries lost its importance and lives are lost more importantly. We decided to put our machine on hold. We would also like to thank our customers, especially those that have been buying from us since ages, that kept us going. Only in late June 2020, we placed an order for a unit of HW-T4SG-50F/GP400. We can’t wait for the machine to arrive and it will be shipped by slow boat to reduce the cost of shipping for something that weighed almost 260 kg. In our next article, we will be writing about our new machine and maybe some videos on the machine, stay tuned!

As always, take care and stay safe!

Hello how are you? I have come to your blog, looking for a little more information about the ZB3545TP, I am from Argentina. Thanks Goolge, and your translator was able to understand very well what your blog was referring to, and I was interested in your experience. I want to tell you that it has helped me a lot, I have a small company, we manufacture electronic products, and a little over a year ago we have been manufacturing some items in SMD. Today we have a small, very basic machine from the Charmhigh brand (CHMT36), and the same one, although it works, has many design flaws, but of course, due to its low cost, you cannot ask for it. I am using it as if it were the great machine, and it does too much. But I discover, from pure experience, and errors (since nobody teaches you anything in SMD, just something on the web, very elementary), that you really need at least two things: that you have a camera, and that you have a motor control system with closed loop. That’s when my search for a new pick and place machine began, already knowing our requirements (such as your experience, no more and no less), and with a budget that was more limited (in my country, inflation and the exchange rate vary upwards). tremendously), one that has a camera and closed loop system (the latter to avoid variations by the mechanism). I saw the NEODEN 4, but it is very expensive, and it does NOT have a closed loop, and its feeders are not common, they are proprietary, it made me hesitate, and I discarded it. On the other hand, I saw in my country, someone who has the ZB3545TS, and I liked it, also he told me about his EXCELLENT experience with the machine, but he was selling it very expensive (USD 19800, which really is a fortune), but I became friends with that person, and learned a lot from that machine, but it turns out that they do not manufacture it anymore to the ZB3545TS, as you say it has a strap now, although I read a lot, that would not be a problem, a strap is cheaper, and if it breaks , I get it at a very low cost. But here comes my doubt, and it has to do with your comment on that model: also it has a strap (I don’t see a problem, in principle), but it says that it has no nozzle calibration, what does it mean? (Cannot calibrate the machine? On the other hand, I had doubts about whether a machine that used Yamaha CL feeders was a good idea (I did not know that in the world Yamaha were already obsolete, but functional), and it ended up helping me decide for YES !! Well, all this I am saying makes sense, considering that I am on the other side of the planet, where my currency is worth 75 times less than the dollar (the official value, since the real value in the street is 135 times less), and on top of that we are very far from China, with what that means. I soundly envy that you can travel and see these huge fairs in person, and see the machines, I will buy something without seeing, just trust my instinct and data that I read from people. I had seen the machine that you bought (congratulations!), the brand and its size made me doubt, it is very heavy (higher cost of freight), and I prefer to continue with one of table, and see what happens to the new machine. It is true, it is a very complicated world economic moment, and n or it seems time to invest, but I want to be prepared for when the economy reactivates, at least in these latitudes. Thank you very much for reading my post, and I send you a virtual hug (even more so with COVID19) from the city of Córdoba, Argentina.

Hi Sebastian,

Thank you for the detailed comment. The belt drive on the ZB3545TP was not an issue for me but I’m only disappointed on why the sales representative didn’t want to mention about this earlier. 2nd, on the older ZB3545TS, the nozzle calibration is performed by opening a secret small cover on the machine that has a sharp marking point and simply pressing the nozzle calibration process button on the software, and the machine will run it automatically. But, this feature was replaced by another different process which was explained in Chinese to me at the exhibition and I couldn’t fully understand due to my bad command of the Chinese language. But, I’m sure it replacement nozzle calibration process should be as good but maybe not as straight forward as the previous machine. But, I do believe with only 38 8 mm feeder slots, you might run out of feeder slot very quickly especially if you use wider feeder (12 mm, 16 mm & 24 mm) although the free area can used to put loose components. Anyhow I would still rate ZB’s software among one of the easiest to use and very intuitive when compared to the other companies. ZB used to be an OEM recipient of HWGC machines. Their older machines were made by HWGC until last year 2019. Regarding Neoden 4, I was the first few persons that saw the machine many years back when it was not released yet. If you were to ask me 5 years on getting a Neoden 4, I might say yes although the pricing is much steeper compared to other machines. But, today you have many other options and with the price of Neoden 4 still pretty much expensive, I would go for any of the Chinese machine like Kayo, Boreytech, HWGC. Our Malaysia currency is also not that great compared to USD and sliding down every year. I do believe the issue with most countries in South America is the excessive tax on import goods. I do think if a commodity is useful to create opportunity to the domestic economy like a pick and place machine, then it shouldn’t be tax or tax too heavily. We are lucky here that pick and place machine is non-taxable item. If you want lower cost shipment, you would have to hunt for it. There are many forwarders on the planet that could give you a very good pricing. Our shipping for the new machine is USD545 (total 300 kg, 1.33 m3) through sea up to our door including all custom clearance processes from Guangzhou (we send it by truck on land from Beijing to this sea port). This provider was used by us for the previous machine and we introduced them to Beijing Glichn. Thanks & take care!

Hello Lim Phang, first of all, I want to thank you for taking the time to answer me, I really appreciate the comment, and it is true, the machine only has 38 Feeders, but for the type of products I manufacture, I hope it works for me, and when I stayed girl, if the economy allows it, I will buy a bigger one like the one you have bought, which I like for its more professional format. But unfortunately I am in the “tail of the world”, and everything is expensive, you live closer to the Chinese. And it is true, that it is an irony that we are taxed on machines, which are to generate work, wealth, but here they punish you, it is really illogical, but that is how they are here in those aspects. Your products are very indos, they look very interesting, and I see that you use Open Hardware. I like to exchange with people of other nationalities, and cultures, and every time I communicate, I see that we all have many things in common, with their nuances, but ultimately we sometimes have the same problems or needs, so pay attention to your comments, since I was reflected in good part. I am already decided to buy the ZB3545TP and by the way I bring a good quality stencil printer table (the one I have has zero precision, my eye makes Caliber), and a 5-zone oven, which I hope is of good quality, and improve the welding, since today I use the famous T962 Reflow Oven Infrared IC brand PUHUI, which works well, but there are areas that do not heat evenly, so I take advantage of little surface of the tray, in addition to slowing down the process (every 7 minutes I take out a small batch of PCB). In the end they all charge me USD 8000, with shipping by free ship, but I still have to add the cost of customs, taxes, truck to my city, I am more than 1000kms from the port, I think it will be almost the same as the machines . Here a Customs Broker charges you for his service, about USD 1000, he is a fortune anywhere in the world, but hey, you are obliged to pay him. We will see how this continues, but I thank you for your time. If you like, you can visit my website, I know that it is in Spanish, but Google can do it, so you translate it without problem into your language, Best of luck with your company, and your future machine, I send you a big greeting from Córdoba, Argentina!

Has the HW-T4SG-50F arrived? if so how is it going? I got a CHMT560p4 recently, and i’m just really curious to see how yours performs.

It has arrived for few weeks now. A bit hectic with custom work at the moment but I have went through the setup and software, it has been good for whatever I have touched so far. All that without me reading any manual although I did skimped through some videos on YouTube! Hardware wise, it is a monster compare to anything in the same price bracket. Getting ready for production now. Will do a video review and written piece once it’s running at full speed!

Great article, looking forward for another blog post with your experience using the machine for production. Btw, what are dimensions of

the machine without monitor/keyboard/mouse stand mounted to the chassis?

It’s 90 cm width, 78 cm height and 114 cm depth. It is definitely not small! Have been using it for production that I don’t have any time to write or capture anything on video. Hopefully once I clear the current workload, I will write about it. It’s really a nice machine to work with.

Hi Lim,

Thank you for your effort and detail. You were very fortunate with your travel timing. Our travel world has been shut down, no shows in the near future.

We have been running a Neoden4 for the last couple of years. For our purpose, it has been ideal and trouble-free. We are looking to upgrade or increase our capacity.

What were the top three factors in your decision?

Do you need an external compressor for the GP400?

Did you consider the Neoden products?

How many feeders did you purchase?

Cheers from Oz

Hi Tony,

Main factor was feeder reliability and consistency, minimum nozzle at least 4, and solid hardware build. The GP400/HW-T4-50F ticks all that. And 1 factor that I do think is very important if not the most important is the product lineup of the company. Companies like HWGC, Kayo, Boreytech all have a similar base for their machine and only scale up by adding more head, feeder and size. They all run the same software and same base hardware. For me, that allows them to concentrate on improving their machine over time across all variant and any bugs in software probably can be applied to all. Yes, with most larger machine you need an external compressor as it is definitely not enough using a small vacuum generator like those smaller machine. I was actually one of those fortunate people to actually saw the Neoden 4 first before it was released back in 2015 (you can read in one of my old post, yes we wanted a machine so badly even 6 years ago) but the price bracket didn’t fit our budget back then. And I didn’t really like the feeder design, so we ended up with a SmallSMT machine in 2018. But they are really nice people. As I have mentioned above, I wanted a machine that factories in China actually use for long runs of production especially in the small medium factories. But, you can expect less support unlike Neoden that was setup more for international market. But, as the machine works perfectly right out of the box, I didn’t really need much help, at least for now. The software can be further improved which they are doing and actually listening to customers. Automatic feeder pickup location is coming up next for example. I’m going to do some video on how-to in December after clearing all my current workload. Cheers!

Thank you Lim. I look forward to your video.

Neoden have been supportive and we have been satisfied with our purchase but I too would like a product which is a little more industrial and modular, enabling future growth and compatability.

Do you have any concerns to date?

BGlichn advises the feeders are Yamaha did you purchase any electric feeders?

Cheers Tony

After 2 months of usage, haven’t bump into any show stopper. The software can be further polished especially better error or warning messages, else it is already doing what it is needed well. Yes, I bought my feeders from Glichn about 30 units of them mix of 8 mm, 12 mm, 16 mm and a vibration feeder. My next batch of purchase will include the electric feeder as I just made a test PCB for 0201. To my surprise, there are owners that uses 0201 using the pneumatic feeders too without the electric feeder. The hardware definitely can do it with a bit of careful setting.

Do you recommend their pneumatic feeders for 0402 or should we pick electric.

I only have the electric feeder to handle my 0402. I think the pneumatic will work just fine for 0402 but it also mean that you can only use for 0402 0.2 mm pitch tape while the electric ones you can use it for 0201, 0402 and 0603 (and above) as the pitch can be adjusted. Having the electric feeder is also very useful when you have very light components especially on plastic tapes where it could easily pop out when used on a pneumatic feeder. But, again if money is an issue (electric is 3x of pneumatic), you can opt for the pneumatic 0402 ones. I personally stopped buying 8 mm pneumatic feeders.

Hi

Which one would you recommend for 0.4mm pitch? I am using PIC32MX series and their TQFP pitch is 0.4mm. I can manage my Neoden 3V sometimes to place them correctly, but lets face it, that machine is not made for that.

Hi Milan,

I don’t own any other machine other than the HW-T4-50F, so I don’t about their performance. Up to now, I have used to down 0.5 mm pitch only, they work just fine. They do mention it could do down to 0.3 mm pitch but that needs verification although I believe the mechanics could.

Hello,

I am seriously considering the GP400 with 40 pneumatic feeders and may include the electrical setup for electric feeders. I am an engineer in which my main concern is support in the US. So far, our communication with Glichn is good, but wondering about support. I can translate via Google, but more over wondering about response times and how they handle or manage warranty, parts and service.

Thank you. Much appreciated!

Kevin

Hi Kevin,

I always speak to them in English and I don’t see why you need to translate. Response time are usually 1 day in my experience. On warranty of parts, you might want them to explain to you.

Hello from Bangkok! Thank you for this really very informative article! It has been incredibly helpful, as well as your other posts on PnP machines such as Neoden. One question I would like to bring up is: how do you rate the usefulness of having your own machine given that some manufacturers now provide PCB assembly at incredibly low prices for small quantities?

As I am moving closer to manufacturing an actual product, I have noticed on multiple occasions that the cost of components as part of a PCBA order at JLC is actually lower than if I buy the components from a distributer. For example, the cheapest SOD123 diode costs 0.46 cents assembled (at qty 200), while at LCSC I’d pay 10% more per part even if I order 3x as many. And getting the components means I still have to program the PnP, reflow the boards, pay for the electricity, throw away the boards not passing QC, account for the time spent by a human operating the machines and of course buy a PnP and an oven first. It really seems like outsourcing PCBA is hard to beat. That may not be true for serious high quantities, but what numbers would we be talking about?

My situation is a bit tricky since my BOM contains an MCU which JLC simply doesn’t have. That means I have to order elsewhere (and probably order a much higher quantity to get the manufacturer even consider my order) – or do it myself. Of course there are benefits in having a PnP. I would be thriled to use one, it would improve prototyping (manually assembling 0.5mm pitch components is a pain), and I generally value it highly to have a deep understanding of the production process, which I would not gain by outsourcing. I was proud of myself for getting my design working with 5 cent microcontroller… but the reality is that I can probably get it manufactured cheaper using a 50 cent microcontroller that the fab has in stock, which is kind of sad.

You may not want to disclose the quantities you are producing, but I would be interested to know your thoughts on this compromise.

Hi Dennis,

I think places like JLC gives an extremely good value if you can fit into their requirement (instead of them to fit into yours). I only used their service once to try out. It’s value for money especially if other costs like import taxes does not overwhelm the total cost. And if they have SMD parts that they don’t have or offer, I doubt that is going to make life easier to assemble afterwards. Coming back to the component costs, I didn’t really check JLC assembly component cost but as I also use a full turnkey PCBA service in Shenzhen for other more complicated high volume custom products, the component price is always higher based on my experience. But, this is from a full-fledged PCBA company. JLC has a total different segment of market. I do believe in Thailand, there are PCBA companies that are quite cost effective last I search many years back.

I have since produced about 2K of boards with variety of complexity and already got back my investment. I think having a machine in-house is good if you are having repeating builds regardless of the volume. I have no prior experience running a machine too but managed to get up to speed in such a short period. If I had the space, I would definitely grow the setup and cascade more machine in the production line.

Thank you for these insights! Just as you said, JLC is all about you fitting their setup and not the other way round. They do have an impressive part library, thus many projects can be made to fit – and there you have an easy cheap way to get a small series assembled. As soon as something doesn’t fit, you have to see whether you can use some kind of workaround or use a different service.

I have talked to one factory in Thailand and they don’t really want to get started unless the job is at least 1000$ (assembly cost only). That threshold may vary, but I think it results from manual work associated with setting up and programming machines, communicating with a customer and sourcing components. The disadvantage of having to commit to a minimum job size actually bugs me more than having to make some adjustments for JLC. So I guess a big advantage of having your own machine is that you can produce as needed and you don’t have to order more than you will be able to sell.

Speaking of space: how did you end up getting this 90x114x90cm thing through your 80cm door?

Yes, having a machine in-house allows you to easily and quickly assemble any volume you want. I have done 50 units all the way to more than 1K of a board variant. Maybe Thailand ain’t that cheap anymore. But having tied down to JLC has it’s own drawbacks too like you are stuck with their PCB specifications (example 0.5 Oz internal copper thickness for multi layer board) and certain quantity only.

I took out the upper half cover and let is sleep on it’s side with few thick mats as “wheels” to slide it through the door. Floors are tiled so they are smooth. Need 4 guys to do the job though.

The inneo or atom by Europlacer is the best in my opinion.

Totally different price bracket and market segment.

Very informative article. When will the next article come out describing the HW-T4SG-50F/GP400 machine and its pros/cons?

Still busy with work but will post a write up soon as we just started using the new software revision which is a major upgrade with many goodies.

Lim, thank you for your wonderful article. I purchased a SMT660 from YX and I am still struggling to use it. I only speak english and the sales person at YX does not understand my questions and they do not really have someone that handles tech support. If you are so inclined and if you can get some extra time, could you please make a video of the setup and run process and maybe highlight some questions that were answered along the way which were not obvious to you when you were learning the system.

I wanted to do this but currently having a down time with the machine as I ignorantly crashed the head into a feeder while I tried to install a feeder onto a live machine! I would say, it is a quick an easy process to setup but there are things that is so crucial but not highlighted enough although it’s important and would be crucial point of whether the pick and place is successful or not. Whenever you have a question to people like Jim of YX, best to use an image/screen capture or video to ask your question.

Sorry to hear of your mishap. I have dealt with Jim extensively with many videos to resolve some problems. It took six months to convince him my high-def camera was faulty.

I hope you get your machine fixed soon.

Started publishing a series of video tutorial/guide on using the HW-T4-50F machine: https://youtu.be/D8Ai-YlF4kE

Hi Lim !

I wonder if you still satisfied with the machine you bought. There is a plan to buy KAYO-A4L but I still hesitate. Do you know someone who use KAYO-A4 ?

Regards,

Ruben

I’m very happy with the machine. Got my investment back within 3 months. I did look at the Kayo but it doesn’t have electric feeder support right out of box (needs some ugly external power supply, etc), feeder count is less and the software on the HWGC machines is definitely far more advance (and updated more frequently). Anyhow, Kayo and HWGC sprung off from the company Boreytech many many years ago, so you could see some similarity but they are quite very different already in the past 5 years or so. Talk to the Liu guy of HWGC to get a feel on the support level you are expecting, then decide from there.

Hi therre

This is a great article especially for noobs in this space on the verge of making a big mistake… thanks alot!!

I have similar requirements and thoughts as you guys stated but the machine mentioned is NOT available for my region (South America) and i have pinpointed this machine. Could you give it a quick glance based on your expertise?

YX Chip Mounter Machine SMT550 (I found on eBay)

Hi Theo,

No, it is available to anywhere in the world.

Contact Liu of HWGC an email and you’ll be in good hands: sjzwglw[at]163[dot]com

Online link said the model is no more available, but i will contact them and reference you.

Thanks alot!!

PS: Why did you go for electric feeders over pneumatic?

Theo,

It’s available, any of their models. Just talk to him directly and he will walk you through. Their machine can support both pneumatic & electric feeder on the same machine. Usually reseller like YX won’t tell you this but will ship default without the electrical ports installed but HWGC will ask if you want them during order process. I use both pneumatic and electrical feeder. Electrical feeder can support small components down to 0201 although I don’t use them. I use them for 0402 & other very light components on plastic tapes like LEDs as they could jump out of the tape pocket easily if using pneumatic feeder. Some people tweak the pneumatic feeder to avoid that issue, but I think using the electrical feeder just completely solve such problem without doing any tweaking. Of course, electrical feeder cost 3X of your pneumatic feeder. Hence I only buy a small handful of them for 0402 and light components. If I have the money, of course I would prefer all of them to be electrical but pneumatic ones works just fine and well enough for now.